THE ALSICO ACADEMY

sustainability

We are rethinking workwear to protect not only the workers of the world, but also the planet we are fortunate to call home. Taking responsibility for the planet, for people, and for progress, we are pioneering a future where industry drives circular change and creates lasting value.

our strategy

the better future system

The Better Future System is our framework that guides how we deliver on our sustainability promises. Each step we take toward environmental, social, and governance (ESG) progress is purposeful and measurable to create lasting value for people, the planet, and our operations. Take a look at how our strategy comes to life.

arx

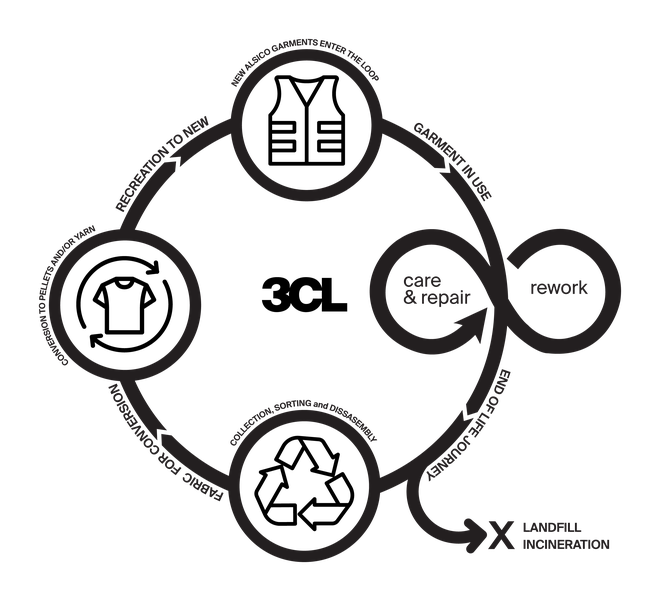

Arx is the home for all alsico initiatives in care, repair, rework, and recycling. Arx has been established to lead the workwear industry toward a circular economy.

3CL

3CL by arx is a groundbreaking project designed to create a fully closed-loop workwear solution. It’s an open initiative that welcomes collaboration with stakeholders across the textile industry.

commercial partnerships

One of our key sustainability partnerships is with professional laundries. They keep garments clean, maintained, and in use for as long as possible. When repairs are no longer possible, we recycle them, closing the loop for a circular textile industry.

These actions are not stand-alone projects, but part of our overall Better Future System strategy.

To learn how these actions create a positive impact, you can read our annual sustainability report.

the better future system

We reduce our negative impact and create lasting value. Our roadmap is build around three pillars: people, planet and operations.

our ESG reporting

As a company, we want to contribute to an economy that respects the planet's boundaries and guarantees basic social rights. We want to take this responsibility by systematically including ecological, social, and economic considerations in our daily policy.

We take responsibility for the impact we have on people and the planet, by actively reducing our negative impact whilst increasing our positive impact.

Vincent Siau, Head of the alsico academy

we are change makers

We are pushing the boundaries of what is possible as a large-scale organisation, doing our part in the world of sustainability. By driving sustainability in innovation, we are making transformational change.

if we want to change the world, we must act

Change does not come from intention alone. It comes from movement,

from bold choices, from doing what has not yet been done.

Alsico has been working tirelessly to develop a framework that enables operations

of our scale to do everything we can to reduce our impact on the world around us.

arx

the future wears circular

Arx is the home for all alsico initiatives in care, repair, rework, and recycling. Arx is designed for circularity, focusing on creating a circular economy for workwear. We encourage customers to return their used garments, which can then be repaired, reworked, or recycled. The goal is to extend the lifecycle of garments, reduce waste and footprint, and promote sustainable practices within the workwear textile industry. Arx has been established to lead the workwear industry toward a circular economy.

introducing 3CL

A key part of the arx initiative is 3CL,

our circularity campaign on closing the loop.

3CL is designed to fundamentally transform the workwear

textile industry by making circularity the new standard.

This is not only about sustainability; it is about redefining

value creation and assurance in the textile supply chain.

3CL

our journey to circular

We are committed to phasing out virgin fossil fuel-based materials and to achieving 90% preferred fibres across our product portfolio by 2040, with an interim target of 40% by 2030, prioritising recycled and regeneratively sourced fibres that lower environmental impact and support circular principles. This approach ensures that circularity starts with responsible material choices, while offering immediate opportunities for innovative suppliers to collaborate with us.

Pauline Latruwe, Sustainability & Education Coordinator

Our ambition is to create a fully integrated, circular supply chain. One where alsico garments are collected, recycled, and reintroduced into production, with every stage validated and improved through stakeholder collaboration. By setting the standards for recyclability, recycled content, and closed-loop operations, we are building a system where market participants rely on our performance for both end-of-life management and new material sourcing.

Vincent Siau, Head of the alsico academy

our journey to closed loop

Alsico is driven to find solutions that not only protect the workers of the world, but also the planet we live on. As a global brand, we are acutely aware of our responsibilities and work tirelessly to solve the most challenging sustainability demands. Our goal is to achieve 90% recycled fibres by 2040, and our first major step has recently been realised, launching our innovative circular garment made from 65% recycled polyester, made from our own end-of-life garments.

After successfully and extensively testing alsico will be launching a new generation of garments powered by fabrics made from polyester that do not rely on virgin fossil fuel, nor on waste from other industries, but on recycled textiles, waste from our own industry. More importantly, to truly close the loop and build our own textile circular economy, alsico managed to incorporate its own waste, even post-consumer in that loop. This was not only demonstrated through recyclability tests, which proved that end-of-life garments can be the source of new generated pellets, but a return supply chain has been set up to ensure nothing goes to waste and the loop can truly be closed.

Vincent Siau, Head of the alsico academy

partnerships

We are aware that in order for us to tackle the toughest challenges, we need to work collaboratively with partners, from our long term partnerships with laundries to our new and exciting partnerships with dynamic, forward thinking companies that are driving global change.

for the change makers, the disruptors, the pioneers and the visionaries...

PARTNERSHIPS

how stakeholders can contribute

Test and certify recyclability: We invite recyclers to conduct professional recyclability assessments of our garments. Your expertise will determine which components are compatible with your recycling technology and identify any barriers to full circularity.

Trial new recycling technologies: We are open to piloting all forms of recycled content and fibre recovery processes, including chemical, mechanical, and hybrid methods. Your innovations are essential to expanding the range of materials that can be reintegrated into our supply chain.

Test recycled content: We seek collaboration with partners who can develop and test fabrics made from recycled fibers, especially those derived from our own post-consumer and post-industrial garments. All new fabrics will undergo rigorous performance and laundering tests according to Alsico’s protocols, ensuring they meet industry standards for durability and usability.

Feedback loop: We encourage iterative testing and feedback to continuously improve the quality and performance of recycled-content fabrics.

Participate in wearer trials: We design and manufacture closed-loop garments for brands committed to circularity. Your participation in wearer satisfaction surveys and feedback sessions is vital to refining our products and meeting real-world needs.

Engage in systemic change: By joining our closed-loop initiative, you become part of a pioneering network shaping the future of more sustainable workwear.

Propose and test solutions: We welcome proposals for technologies and systems that support repair, collection, sorting, or dismantling. After initial review, promising solutions will be trialed and assessed.

"Join us to become a key player in the next-generation supply chain; where circularity, quality and innovation define the market, and where together, we set the benchmark for the industry of tomorrow."

Vincent Siau, Head of the alsico academy

PARTNERSHIPS

two decades of experience

For nearly twenty years, we have been collecting end-of-life

garments and researching the best “retirement plan” for textiles.

Our alsico academy team has tested many recycling

methods and learned what works best, from mechanical

shredding to advanced chemical recycling. These insights

help us continuously improve our recycling solutions

and our garment development.

PARTNERSHIPS

keeping clothes in use longer with our laundry partners

One of our most successful partnerships in sustainability is our partnerships with laundries, ensuring our customers’ garments are kept clean and neatly finished but also in use for as long as possible. When garments are damaged, they return to us for repairs and are then put back into circulation. Only when repairs are no longer possible, do we consider the garment to have reached its ‘end of life’, at which point we begin the recycling process.

PARTNERSHIPS

partnerships driving circularity

We are rethinking workwear to protect not only the workers of the world but also the planet we all call home. In partnership with Sixone Labs and Stuff4Life, we are turning end-of-life garments into new raw materials, and cutting down textile waste instead of it ending up in landfill or incineration. Together, we are creating closed-loop solutions for the workwear industry and achieving what many once thought impossible: a fully circular, industrial-scale workwear system. And we’re not stopping here, we’re partnering with leading recyclers to keep finding solutions to close the loop.

Sixone Labs

Turning tons of end-of-life garments into polyester pellets, which are spun into new yarns and used to produce new workwear.

Stuff4Life

Innovating a recycling method for reflective stripes by reclaiming and reusing the glass beads to create new high-performance stripes.

partnerships

verified efforts and responsible partnerships

Oekotex Standard 100

This certification ensures textiles are tested for harmful substances, helping protect the health of wearers. It supports our commitment to safety and responsible sourcing.

Better Cotton Initiative

As part of a broader commitment to sustainability, partnership with Better Cotton supports the global improvement of cotton farming. Since 2021, the goal has been to source only preferred fibres by 2040, with 100% of our cotton as BCI Cotton, recycled cotton, organic cotton, Fairtrade cotton etc.

the better future system

We reduce our negative impact and create lasting value. Our roadmap is build around three pillars: people, planet and operations.

We want to do the right things, but we also want to do things right. Therefore, we have created the Better Future System. We are engineers. We know how to run efficient factories, how to make great and qualitative garments. We are process driven and know how important assurance systems, like our quality assurance system, are. We simply applied the principles of a robust assurance system with processes and preventive and corrective actions, to our sustainability program.

the better future system

how we create impact today

the better future system

from commitment to action

We not only established a sustainability strategy, but we also made sure its implementation through task forces is wide-spread throughout our group. We don’t have a sustainability department per say, sustainability has become a way of doing things and has seeped through every part of our organization, anchored in our DNA. We have established our objectives over 3-time horizons, and over three topics: environmental, social and governance.

our ESG reporting

We aim to build an economy that respects the planet’s limits and guarantees fundamental social rights. Responsible manufacturing means taking responsibility for our environmental and social impact. Our Oeko-Tex STeP certified production units ensure cost efficiency and a future-ready supply chain. These principles shape our daily policy and are documented in our ESG report, reflecting our commitment to full transparency.

our ESG reporting

how we get there

We're proud to present our 2024 Environmental, Social, and Governance (ESG) report, highlighting alsico Group's achievements in sustainability, inclusivity, and ethical practices. This report reflects our dedication to reducing environmental impact, empowering our workforce, and upholding the highest standards in everything we do.

our esg reporting

we are continuously working on making a positive impact on the environment and the people

As a company, we want to contribute to an economy that respects the planet's boundaries and guarantees basic social rights. We want to take this responsibility by systematically including ecological, social, and economic considerations in our daily policy.

contact

request more information

latest sustainability stories